1. Technical principle: complementarity of degree data acquisition

The central role of ethernet pressure scanners

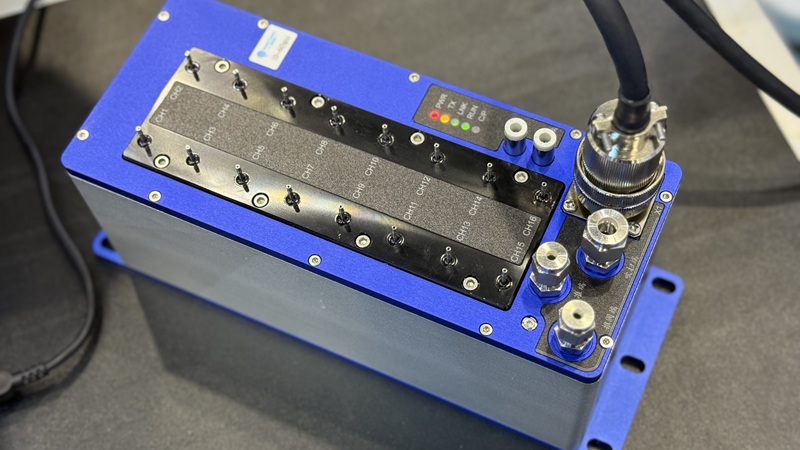

ethernet pressure scanners is a multi-channel pressure sensor integration device, which can simultaneously collect pressure data from tens to hundreds of measurement points on the surface of the model, and then convert the pressure signal into a signal through a high-precision sensor. For example, in an aircraft wing test, ethernet pressure scanners can accurately measure the surface pressure gradient at different angles of attack and identify the airflow separation area.

Analytical Ability of Five-Hole Probe for Dynamic Flow Field

Based on the principle of Bernoulli equation and continuity equation, the five-hole probe can sense the direction, velocity, total pressure and static pressure of the air flow through five hole positions, and can calculate three-dimensional flow field parameters (such as Mach number and turbulence intensity). Suitable for complex flow regimes (such as transonic speed, shock wave interference), and data reliability can be improved through wind tunnel calibration. In a high-speed wind tunnel test, the five-hole probe can capture the shock position and vortex structure, which provides a key basis for optimizing the aerodynamic shape.

2. Synergistic advantage: more refined analysis of flow field

Fusion Verification of Surface and Flow Data

The surface pressure distribution data provided by ethernet pressure scanners can be cross-validated with the three-dimensional flow field parameters of the five-hole probe. For example, in the automotive wind tunnel test, ethernet pressure scanners measure the surface pressure of the body, and the five-hole probe simultaneously analyzes the turbulence characteristics of the wake region. The combination of the two can verify the accuracy of computational fluid dynamics (CFD) simulation and design the iteration period.

Through joint data analysis, core parameters such as lift coefficients, drag coefficients, and moment coefficients can be extracted, and local flow anomalies (such as boundary layer separation, vortex shedding) can be identified. For example, in the test of turbine machinery blades, the two cooperate to find the impact of blade tip leakage flow on efficiency and guide the further optimization of blade profiles.

3. Examples of typical application scenarios

Aircraft aerodynamic shape optimization: In the wind tunnel experiment, the combination of ethernet pressure scanners and five-hole probes is used to measure the surface pressure of the aircraft and the shock wave interference flow field, which significantly improves the aerodynamic efficiency of the aircraft test.

Automobile aerodynamics: Through the joint analysis of the pressure distribution on the body surface and the wake turbulence characteristics, the drag coefficient and the optimization of the air flow path of the cooling system improve fuel economy.

Turbine mechanical flow field diagnosis: In the cascade test, the combination of the two can reveal the secondary flow loss in the blade channel, providing data support for improving turbine efficiency.

As a leading company in the field of flow field measurement and control, Windtuner Technology provides a full-chain solution for the customization of ethernet pressure scanners and five-hole probes with its strong R&D strength and flexible services. According to the special needs of users in different industries, Windtuner can modularize the core parameters such as the range of ethernet pressure scanners, which can cover the pressure range of 0-850psi, with an accuracy of ± 0.05% FS, and integrate high temperature compensation algorithms to cope with extremes. The customization of the five-hole probe can use 3D printing technology. The aperture of the porous aerodynamic probe can be less than 0.2 mm, with stronger aerodynamic performance, and can accurately capture micro-flow field characteristics such as blade tip eddy current. In terms of service response, Windtuner technology can greatly shorten the supply cycle of customized equipment. This double guarantee of "hardware customization service extension" not only solves the pain points of poor versatility and slow iteration of flow field measurement equipment, but also promotes, Refined research and development process in new energy and other fields.