Supporting Control System

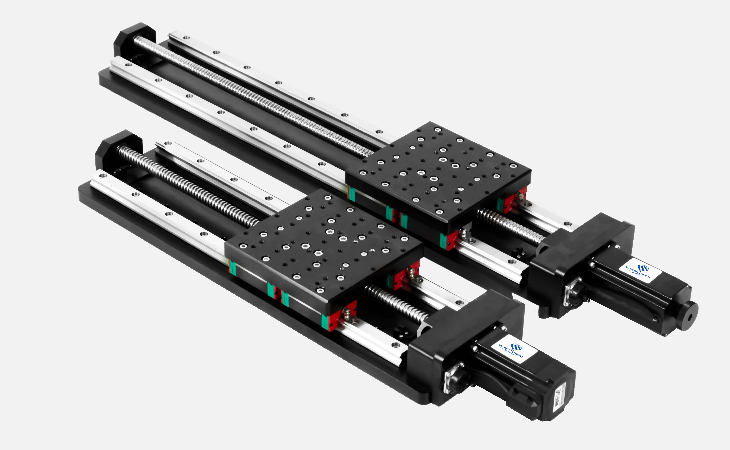

Electric displacement mechanism

Motion controller

Technical data

CourseCustomisable on request,standard products are multiples of 50mm

Axial clearance<0.02mm

Screw lead4mm for less than 300mm;5mm for 400mm~1000mm;10mm for over 1000mm

Repetitive positioning accuracy<0.005mm

Stepping motor(1.8°)42/57/86

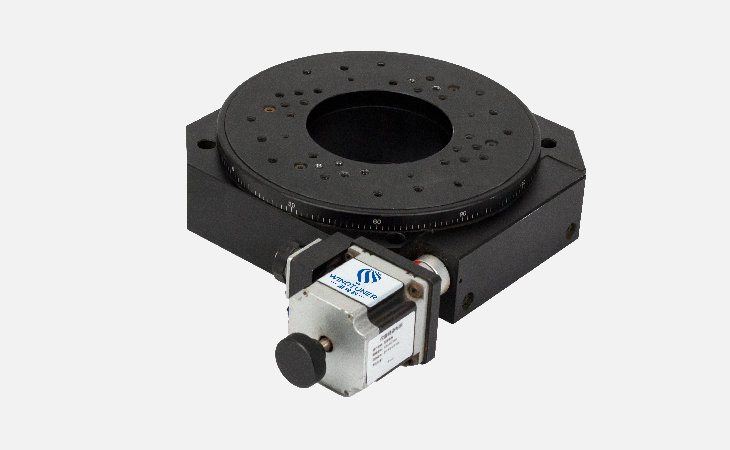

Diameter of platform60mm,100mm,200mm,300mm,400mm

Transmission ratio90:1,180:1,270:1,720:1

Resolution0.0003°,0.0002°,0.0001°,0.000039°

Repetitive positioning accuracy<0.01°,<0.005°,<0.004°,<0.003°

Stepping motor(1.8°)42/57

Power supply220VAC

Output current(per shaft)(0.1~5.6)A Adjustable

Impulse response frequency(0~200)kHz

Network type10/100M Adaptive Ethernet

Network protocolTCP/IP

Working temperature(0~50)℃

Storage temperature(-20~65)℃

Limit signal input2/Shaft

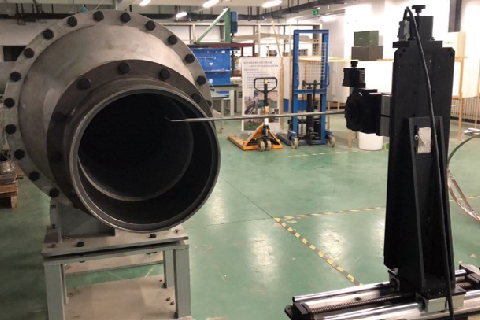

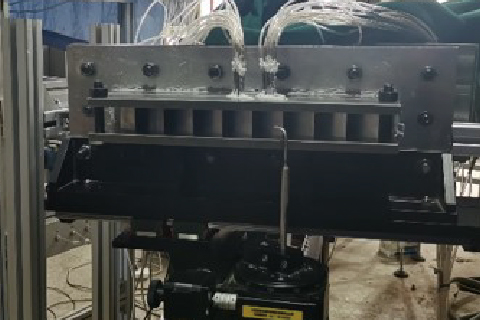

Product Gallery

Supporting control system

Advantages of electric displacement mechanism

Heavy load translating and rotary platforms can be customed.Worm gears are precisely matched for comfortable movement and lowbacklash.

The transmission adopts worm gear structure,the platform can be rotatedforward and backward freely.

Stepping motor as standard,can be replaced by servo motor,suitable fordifferent applications

Stepping motor and worm gear are connected by flexible coupling,withsynchronous transmission and low noise.

The cleverly designed clearance elimination structure can adjust the clearance caused by long-term use.

The rotating shaft system is made of bearing steel,which has high coordination,great load and long service life.

The diameter of the central hole is limited by tolerance,and the central hole coincides with the centre of rotation,which is convenient for positioning.

The outer ring of the platform is ascaled ring,the surrounding laser engraved scale can ratote relative to the platform,which is convenient for reading and initial positioning.

Advantages of motion controller

Asymmetric linear acceleration/deceleration drive,S-curve acceleration/deceleration drive.The number of output pulses or drive speed can be changed during motion.

Logical position,actual position,drive speed,acceleration speed,acceleration/deceleration status(accelerating,constant speed,decelerating)can be read in real time during motion.

There are two 32-bit comparison registers for every shaft to compare the position size of the logical or actual position counters,which can be used for software limits.

Can receive various signals from the servo motor drive,such as hardware limit signals,position signals,alarm signals,etc,32-bit increment/decrement counter used for additional encoder.

The corresponding software parameters can be modified according to the hardware parameters of the electric displacement mechanism,which can beflexibly adapted to the control of variouselectric displacement mechanisms.

Choose the product or service you need!

Choose the product or service you need!Our solution

Find out how we can help you

Support center

Know our products in detail

FAQs at a glance