Declaration

This manual is applicable to the WTNDAQ-P-1605 series products designed and manufactured by our company.It is prepared to help users familiarized with and correctly use the product.This manual is based on the Chinese version.If there are any discrepancies in understanding different language versions,the Chinese version shall prevail.If this manual is revised,no separate notification will be provided for the manuals that have already been issued.Product Introduction

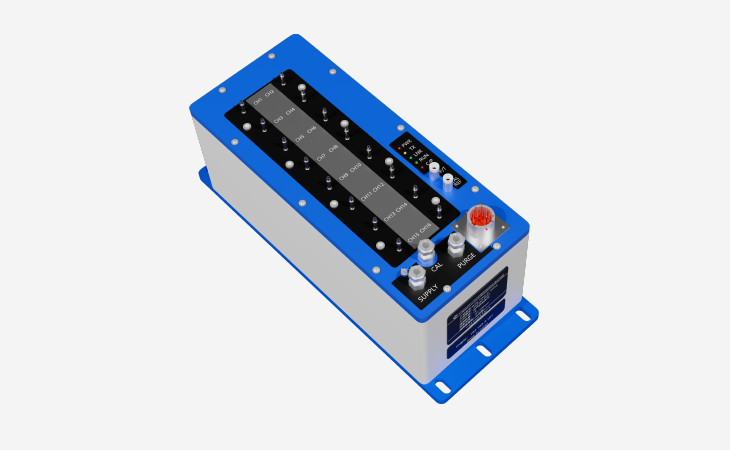

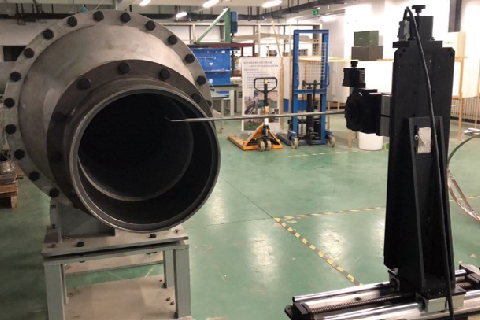

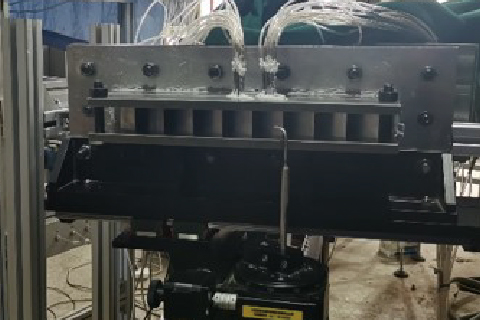

WTNDAQ-P-1605S (hereinafter referred to as "1605S") is a high-performance and highprecision pressure acquisition equipment. It is designed for dry, non-corrosive gas measurement and is widely used for pressure measurement in turbine test benches and wind tunnel test benches.

The 1605S integrates 16 pressure sensor modules. Each sensor module is encapsulated in a robust and compact casing. Each sensor module consists of a microprocessor, a pressure sensor, a temperature sensor and EEPROM memory. The EEPROM holds key data for sensor calibration, as well as identification information such as measurement ranges, range codes, and other factoryspecific identifiers. The microprocessor uses the data stored in the EEPROM memory to correct the sensor's offset, range, linearity and thermal errors. The independent encapsulation of each sensor module makes the equipment easy to replace and service.

The 1605S scanner features a maintenance-free pneumatic valve system. When an external power source is connected, users can switch the valve bodies through commands. 1605 supports three operating modes: "Run Mode (RUN)", "Calibration Mode (CAL)", and "Purge Mode(PURGE)". Users can perform tasks such as data acquisition, zero calibration, full-scale calibration, custom multipoint calibration, and pipeline purging and cleaning in different operating modes.

The 1605SS supports the IEEE1588S protocol and can use UDP broadcasts to obtain the host PTP time and synchronize it locally, ensuring long-term accuracy of the equipment clock. It has a built-in battery with a lifespan of 6 years, providing power to the clock chip for an extended period.