Taking the wind tunnel test of a certain type of stealth fighter as an example, more than 800 pressure measuring points need to be deployed on the wing surface, and the manual switching system takes more than 72 hours, and the data error rate is as high as 3%. Among them, pressure measurement is an important index to evaluate the performance of aircraft, and its accuracy directly affects the safety and reliability of the entire flight mission.

Importance of Ethernet Intelligent Pressure Scanners: During the development and testing phase of aircraft, pressure data is an important parameter to measure engine efficiency, aerodynamic performance and structural integrity. Traditional pressure measurement methods often rely on a single pressure sensor or manually switch multiple sensors for multi-point monitoring. This method is not only time-consuming and laborious, but also difficult to ensure the consistency and accuracy of data.

In contrast, WindtunerEthernet Intelligent Pressure Scanners enables simultaneous monitoring of multiple pressure points through multiple technical advantages, and can quickly and accurately collect large amounts of data.

1.Technical Advantages of WindtunerEthernet Intelligent Pressure Scanners

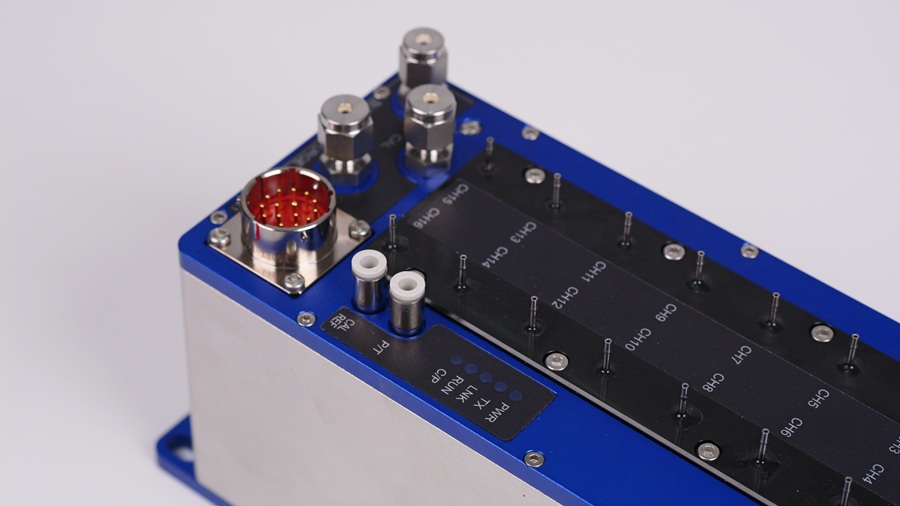

Windtuner Ethernet Intelligent Pressure Scanners integrates advanced sensing technology and intelligent control systems with significant technical advantages: High-precision measurement: Windtuner Ethernet Intelligent Pressure Scanners uses 16 independent pressure sensor modules, each of which is precisely calibrated with a measurement accuracy of ± 0.05% FS, which can capture the pressure changes on the surface of the aircraft in real time and accurately.

Multi-channel parallel sampling: Windtuner Ethernet Intelligent Pressure Scanners supports multi-channel parallel sampling with a sampling frequency of up to 500Hz, which can monitor pressure data at multiple key points at the same time and improve data acquisition efficiency.

Intelligent operation: Windtuner Ethernet Intelligent Pressure Scanners has a built-in maintenance-free pneumatic valve circuit system, which supports free switching between "operation mode", "calibration mode" and "purge mode" to realize automatic operation, reduce manual intervention and improve work efficiency. Remote upgrade and networking capabilities: WindtunerEthernet Intelligent Pressure Scanners supports remote firmware updates to keep the system stable. At the same time, Multi-device networking capabilities allow the construction of distributed data acquisition systems to realize multi-device collaborative work and automated acquisition.

Wide Range Coverage: Wide range coverage, from-2.5 kpa to 1000psi, with multiple range segments to choose from, suitable for a variety of high and low pressure environments.、

2.Application in aircraft support test

Windtuner Ethernet Intelligent Pressure Scanners play an important role in aircraft support tests:Flight performance verification: By accurately measuring the pressure distribution at each point on the surface of the aircraft, detailed data support is provided for evaluating the aerodynamic performance of the aircraft.

System safety test: In harsh working conditions, such as high temperature and high pressure environments, Windtuner Ethernet Intelligent Pressure Scanners can work stably, provide reliable pressure data, and help engineers evaluate the system safety of aircraft.

Troubleshooting and optimization: Through long-term monitoring and data analysis, the equipment can find potential failure points and provide guidance for the optimal design and maintenance of aircraft.

Windtuner Ethernet Intelligent Pressure Scanners is making continuous efforts to improve the efficiency and accuracy of aircraft tests through precision design, intelligent algorithm empowerment and ecological service mode.