1. Core performance duel: a contest between accuracy and stability

1.1. Measurement accuracy: evenly matched, all of which are professional standards

DSA3217: Its accuracy is its biggest highlight. After calibration, the differential pressure measurement accuracy can reach ± 0.05% FS (full scale), and the absolute pressure accuracy is also ± 0.05% FS. For example, the error of a sensor with a range of 100 psi can be controlled within ± 0. 05 psi, which is sufficient for most high-precision scientific research and certification tests.

Windtuner ethernet pressure scanners: Its full-scale measurement accuracy can also reach ± 0.05% FS, and it has a built-in high and low temperature AI compensation algorithm, which can effectively suppress temperature drift and ensure measurement stability in the full temperature range.

Conclusion: Both of them have reached the international advanced level in the core precision index, and they are indistinguishable.

1.2. Channel capability and integration

DSA3217: A single module provides 16 pressure channels and uses two independent 8-channel sensor groups, each sharing a calibration valve and reference gas path. This design is mature and reliable, but the wiring is relatively complex (using a 1/16 "pipe connection).

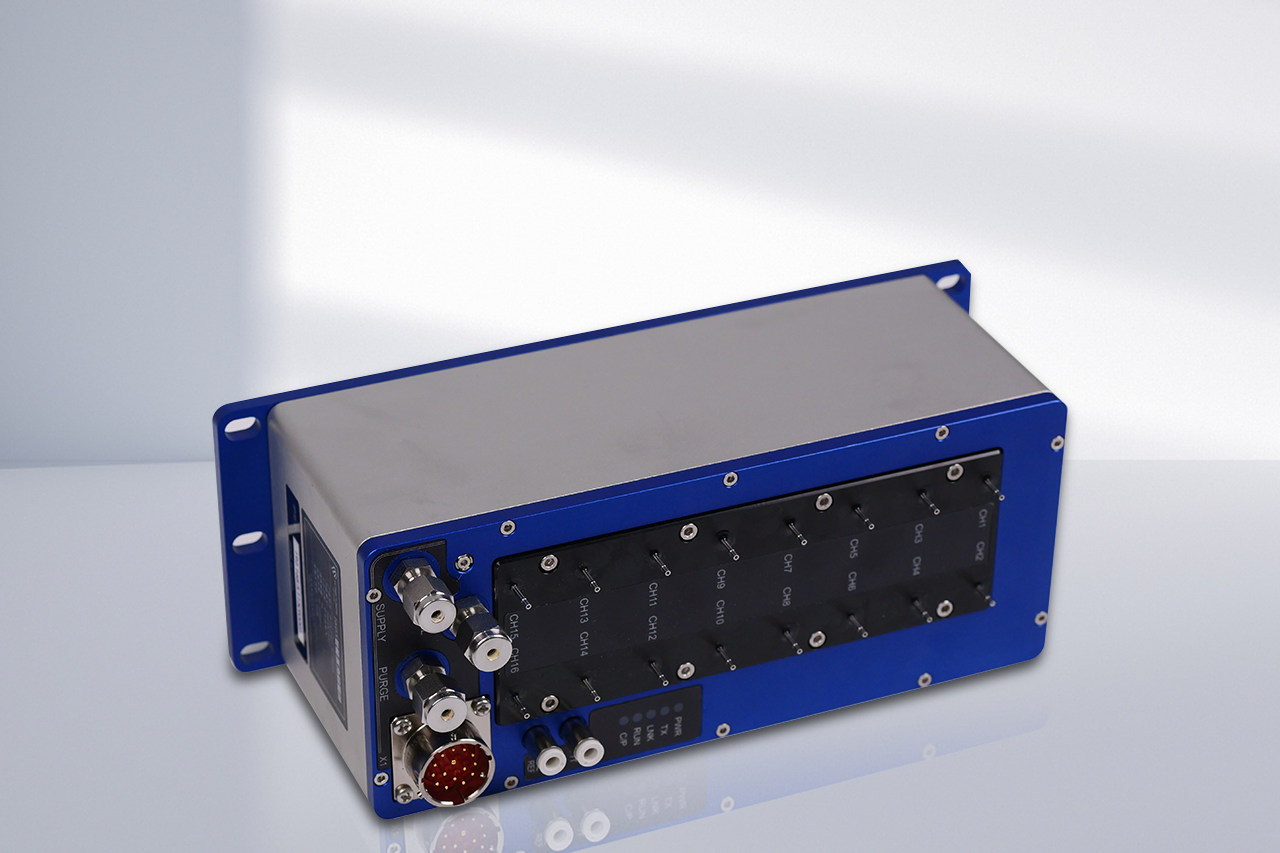

Windtuner: It also provides 16-channel or higher-density module options, and Windtuner intelligent pressure valve is also equipped with atmospheric pressure and atmospheric temperature modules in addition to sensor modules, and supports IEEE1588V2 communication protocol, only one network cable and one power cable (supports PoE power supply) can complete all connections, the wiring complexity is more than 80%, and the "spider web" wiring is completely farewell.

Conclusion: In terms of channel scalability and system integration simplicity, Windtuner's modular design is better, which greatly improves the construction efficiency.

2. Efficiency and ease of use: the revolution of modern experience

This is the field with the greatest difference between the two, and it is also directly related to the work efficiency of scientific researchers.

2.1. Operation and software experience

DSA3217: Software control is mainly implemented through Command Line instructions (Command Line). Users need to learn and enter text commands such as SET FPS 5, CALZ, SCAN, etc. for configuration, calibration, and acquisition. While powerful and flexible, the learning curve is steep and not friendly enough for newbies. Its supporting software, such as ScanTel, LabVIEW configuration tool, etc., has a relative interface.

Windtuner ethernet pressure scanners: Equipped with WindLabX series measurement and control software, it adopts LabVIEW visual programming and provides a graphical operation interface. The software supports measurement management, equipment management, real-time data display, acquisition, storage and playback, with high functional integration and fast hands-on speed. Its software is also deeply compatible with the motion control system, which can realize automatic scanning in the wind tunnel and has a higher degree of intelligence. In addition, Windtuner also provides customers with a complete set of three-dimensional flow field measurement and control system service solutions, and can provide various product solutions according to customer needs.

Conclusion: Windtuner has achieved intergenerational transcendence in terms of software ease of use and automation integration, which has greatly increased the operating threshold and labor cost.

3. Reliability and applicability

DSA3217: The shell is made of stainless steel and has a splash-proof design. The operating temperature is 0 ~ 60 °C, and the temperature compensation range is 0 ~ 69 °C. Its sister model, the DSA3218, is more robust and suitable for harsher working conditions (e.g. flight tests, gas turbine tests)

Windtuner ethernet pressure scanners: The data shows that its operating temperature range is 0 ~ 60 °C, with a wide temperature design and stability through algorithm compensation. Its products also follow strict production standards. Moreover, relying on Windtuner, it has the first CNAS-approved calibration wind tunnel laboratory in China. Each Windtuner ethernet pressure scanners has been calibrated before leaving the factory, and a CNAS-approved calibration report has been issued. Customers can use the product directly after getting it.

CONCLUSION: Both of them can operate reliably in typical laboratories. For extremely harsh industrial sites, the DSA3218 may be a more specialized choice.

Conclusion

Choose DSA3217: If your project budget is sufficient, you have a strong demand for the reliability and historical reputation of imported brands, or the work is extremely harsh (such as strong vibration, wide temperature range testing), DSA3217 is still a trustworthy choice.

Choose Windtuner ethernet pressure scanners: At present, the domestic market share of Windtuner ethernet pressure scanners is more prominent among similar products. If you pursue high cost performance, ultra-high precision, want rapid deployment, simplified wiring, and focus on localized services and software ease of use, then Windtuner is undoubtedly a better solution.

Final recommendation:

For most scientific research institutes, university laboratories and industrial R&D departments, Windtuner ethernet pressure scanners have more prominent comprehensive advantages in precision, ease of use and cost control.