1. Flow field monitoring between compressor stages

Limited by the number of sensors, it is difficult to penetrate into every detail of the compressor. For example, Windtuner's ethernet pressure scanners can be collected through multi-probe collaboration, providing a new solution. It can connect three-hole total pressure probe, five-hole probe and other equipment synchronously, penetrate into the gaps of multiple stages of the compressor impeller, and capture the speed, direction and pressure distribution of the airflow in real time. The application of this technology not only improves the monitoring accuracy, but also enables the dynamic changes of airflow to be captured in real time, thus providing reliable data support for engine performance optimization and fault warning.

2. Intake air distortion test

When an aircraft flies at a high angle of attack, the inlet flow separation may lead to uneven pressure distribution at the engine inlet, and even cause compressor surge or blade fracture in severe cases. Windtuner's ethernet pressure scanners adopt a high sampling rate of 500Hz, which can accurately capture pressure changes at multiple measurement points in the inlet under transient conditions and generate real-time pressure cloud images. This technology can monitor the "breathing" status of the engine during the flight of the aircraft, helping R&D personnel to ensure the safety of the engine operation in a timely manner.

3. Motion synchronous acquisition

The wind tunnel test often requires a step-by-step model angle, which is cumbersome and has a low data acquisition density. Harbin Institute of Pneumatics has linked ethernet pressure scanners with VXI force measurement system to realize the motion synchronous acquisition technology. In the range of-4 ° to 20 ° angle of attack, 2112 sets of pressure-angle correlation data can be obtained in a single test by scanning at a rate of 0.25 °/s, and the efficiency is 60% higher than that of the method. The application of this technology greatly shortens the test period, improves the test accuracy and the density of data acquisition.

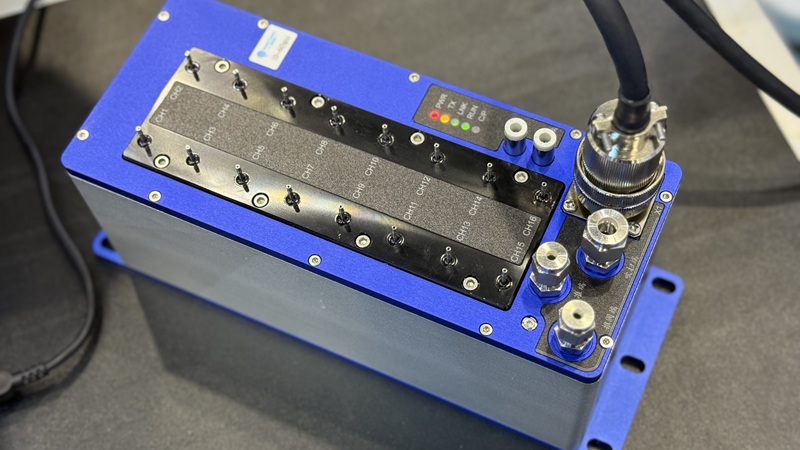

4. Multi-channel pressure synchronous acquisition in complex flow channels

In some complex engine tests, such as high temperature and high pressure regions such as inlet and afterburner, pressure measurement faces higher technical challenges. Windtuner's multiple ethernet pressure scanners can synchronously realize 128-channel synchronous acquisition, and have automatic calibration and pipeline purge functions, which can adapt to ignition tests under high temperature and high pressure. This technology greatly improves the accuracy of complex flow channel pressure data acquisition, and provides a guarantee for the safety and stability of the engine under extreme working conditions.

5. Inlet Test of Hypersonic Vehicle

ethernet pressure scanners also play an important role in the research and development of hypersonic vehicles. The high-temperature ethernet pressure scanners developed by a domestic research institute have been successfully applied to aftercombustion chambers up to 1000 °C. With its high temperature resistance, it provides accurate pressure monitoring data.

6. Pressure test of the whole machine test bench

For the performance evaluation of the whole engine, Windtuner ethernet pressure scanners also performed well. Combined with the total pressure probe and the five-hole probe and other equipment, the full parameters of the engine pressure distribution can be collected under steady state and extreme working conditions. Through the analysis of these data, it can provide a solid foundation for engine performance optimization and safety assessment.